Since the introduction of PM, the predecessor of TPM, to Japan in 1951, Seiichi Nakajima has dedicated over half century to influence the concept of PM and TPM as a leader, and continues to this day.

In these days, increasing numbers of TPM Award winners in overseas evidence that over 50 years of his committed effort is a genuine and valuable dedication to not only the Japanese manufacturing industry but also for manufacturing industry all over the world. Without his remarkable effort, TPM and manufacturing industry would not have been what it is today.

TPM is a unique Japanese systems of managerial expertise.

Developed from PM (preventive maintenance)style of US in 1950s.

Subsequently developed to its present state by JIPM

Now, TPM promotes entire company structures every line of businesses and all parts of the world.

TPM is implemented company wide.

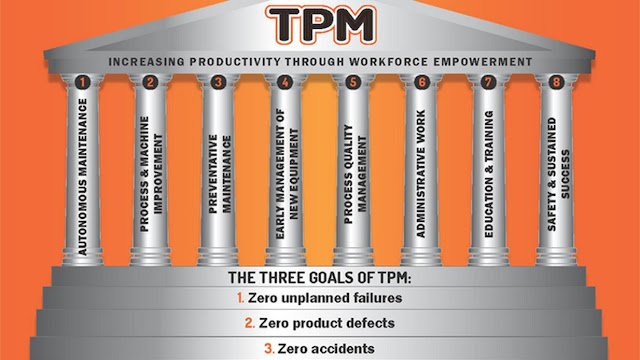

TPM Principles :

The eight pillars of TPM are mostly focused on proactive and preventive techniques for improving equipment reliability:

- Autonomous Maintenance - Operators who use all of their senses to help identify causes for losses

- Focused Improvement - Scientific approach to problem solving to eliminate losses from the factory

- Planned Maintenance - Professional maintenance activities performed by trained mechanics and engineers

- Quality management - Scientific and statistical approach to identifying defects and eliminating the cause of them

- Early/equipment management - Scientific introduction of equipment and design concepts that eliminate losses and make it easier to make defect free production efficiently.

- Education and Training - Support to continuous improvement of knowledge of all workers and management

- Administrative & office TPM - Using TPM tools to improve all the support aspects of a manufacturing plant including production scheduling, materials management and information flow, As well as increasing moral of individuals and offering awards to well deserving employees for increasing their morals.

- Safety Health Environmental conditions