Advanced product quality planning (APQP) is a framework of procedures and techniques used to develop products in industry, particularly in the automotive industry. It is similar to the concept of Design for Six Sigma (DFSS).

According to the Automotive Industry Action Group (AIAG), the purpose of APQP is "to produce a product quality plan which will support development of a product or service that will satisfy the customer." It is a product development process employed by General Motors, Ford, Chrysler, and their suppliers. APQP serves as a guide in the development process and also a standard way to share results between suppliers and automotive companies. APQP specifies three phases: Development, Industrialization, and Product Launch. Through these phases, 23 main topics will be monitored. These topics must be completed before the production is started. They include the following aspects: design robustness, design testing, and specification compliance, production process design, quality inspection standards, process capability, production capacity, product packaging, product testing, and operator training plan.

APQP focuses on:

- Up-front quality planning

- Determining if customers are satisfied by evaluating the output and supporting continual improvement

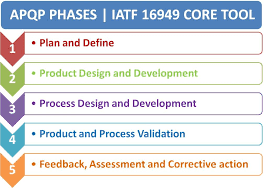

APQP consists of five phases:

- Plan and define program

- Product design and development verification

- Process design and development verification

- Product and process validation and production feedback

- Launch, assessment, and corrective action

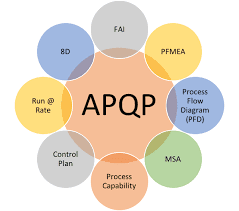

The APQP process has seven major elements:

- Understanding the needs of the customer

- Proactive feedback and corrective action

- Designing within the process capabilities

- Analyzing and mitigating failure modes

- Verification and validation

- Design reviews

- Control special/critical characteristics

Useful Links to Read:

01. history-of-total-productive-maintenance

02. why-implement-total-productive

03. what-is-tpm

04. 12-steps-for-tpm-implementation

05. typical-tpm-organizational-chart

06. effectiveness-of-tpm

07. 5-principles-in-tpm-development

08. purpose-and-main-activities-of-kk

09. purpose-and-activities-of-jh-pillar

10. purpose-activity-of-pm-pillar

11. purpose-activities-of-qm-pillar

12. purpose-and-activity-of-dm-pillar

13. purpose-and-activity-of-otpm-pillar

14. purpose-and-activity-of-e-pillar

15. purpose-and-activity-of-she-pillar

16. company-wide-tpm

17. jishu-hozen-information

18. ishu-hozen-equipment-deterioration

19. role-of-production-maintenance-in-jh

20. jishu-hozen-step-1

21. 1s-2s-implementation

22. jh-step-01-abnormalities

23. exposing-seven-types-of-abnormality

24. 2-unfulfilled-basic-condition

25. 3inaccessible-places

26. 4-contamination-sources

27. 5-quality-defect-sources

28. 6-unnecessary-non-urgent-items

29. 7-unsafe-places

30. jishu-hozen-step2

31. jishu-hozen-step-3

32. one-point-lesson-opl

33. visual-control-visual-management

34. 35. what-is-smed

36. why-energy-conservation

37. mobile-phone-handling-important-tips

38. kaizen-way-of-life

39. what-is-kaizen

40. techniques-used-in-kaizen

41. tmv-mba-project-guideline

42. gdmm-project-guidelines

43. importance-of-energy-conservation

44. global-warming-25-tips

45. latest-abcd-from-nursery-school

46. world-environment-day-5th-june

47. be-proud-to-be-engineer-happy

48. lean-tools-hidden-waste

49. waste-over-production

50. wastes-of-defects-rework

51. waste-of-motion

52. Wastes of Transportation

53. 2014 FIFA World Cup Brazil

54. Self Confidence Vs Over confidence

55. How to build self confidence-Hard Work